It is popularly called PPF taken from the initial letters of Paint Protection Film. The purpose of PPF is to protect the body surface, prevention of fading colors and scratch protection, etc.

Most PPF products are from the U.S. and the manufacturers are limted. Within such industry, Syncshield was developed in Japan by SENSHA in cooperation with several Japanese film related manufacturers and will be the new flagship product of the SENSHA Brand.

Compared to other popular products in the market, Syncshield has many unique performance enhanced features added. Its on a performance level of its own.

Self-recovery

Anti-fouling

Water repellent

Oil repellent

Anti-solvent

Each Syncshield has a serial number assigned. Customers may receive the serial number information from the SENSHA family shop that served you. Enter the number in the Serial Search box and it will show results containing the shipped date from Japan, the arrival date in your country, service shop name, your car model and body color. If the serial number you enter shows result of "Not Found", then the PPF you purchaesed is not an authenticated one. By confirming the authenticity through this system, we guarantee it is 100% made by SENSHA.

This video shows the performance of our Syncshield compared against other products.

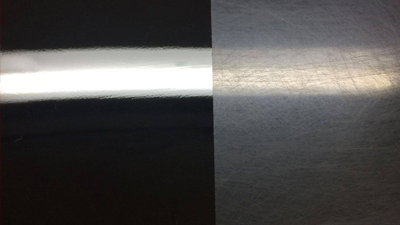

This picture shows Syncshield pasted on a dark blue car body panel. As you see, an old and dull looking body panel (right half side of picture) is revived with luster and looking like a high-class brand new body (left half side of picture). By applying Syncshield, you can restore the luster and shine of the body surface on your car just like brand new. You can experience extra-shine if your car is new, a deeper luster if it has condensed color.

The most unique character of Syncshield is its scratch resistancy. When you get fine scratches, our PPF carries a "Self Healing Effect" to prevent fine scratches from getting on your car. This is called Soft Coating which is a brand new technology born from the completely opposite idea of Hard Coating used for protection films for smart phones and windshields and fixes the scratches immediately (Please see video, the scratches caused by wire brush is fixed immediately). Other brand products require heat to fix the scratches, whereas Syncshield heals under normal temperature. No hot air or hot water necessary!

Syncshield has excellent water repellency. The result of water contact angle test was 110℃, which is the level equivalent to water repellent glass coating. No need for glass coating or waxing.

Tars and pitches from asphalt roads stick on the vehicle body. Oily stains from exhaust gas also is a reason for the vehicle to get dirty. To prevent these stubborn stains, we strengthened oil repellency also. Contact angle test using hexadecane resulted in 65℃. This video shows what happens when aerozole engine parts cleaner is sprayed on our PPF.

Vehicles are exposed not only to tars and pitches, but also to other liquid like maintenance cleaners. Gasoline, etc. Many of these liquid contain organic solvent which cause severe blemishes to PPF. Syncshield strengthened solvent resistancy in addition to the oil repellency. This video features the tests conducted to showcase the different performances level of Syncshield.

Generally, PVC or TPU was used as the base material (film) for PPF. The positive for PVC is the low cost of production. On the other hand, the negative is the weak weatherability, not much fit as the material for PPF.

High transparancy is a must for basic feature. We strongly focused on high transparency upon development in order to keep the texture of body colors different by each model. No one will notice that PPF is applied and being unnoticed is a very important basic feature for a PPF.

The ultimate smoothness Syncshield pursued is one of a mirror surface. We realized such smoothness.The ultimate smoothness, so no one will notice that PPF is applied, is a very important feature for a PPF.

Syncshield's urethane film was developed focusing on the suppleness to follow the sophisticated tertiary curved surface of a car body. This allowed for application without excessive pulling or additional heat and realized higher durability and anti-chipping performance.

TPU used for Syncshield is a non-yellowing type material with one of the highest quality.

The adhesive used for Syncshield was selected from 200 different types and adjusted to match a flexible urethane film. The adhesive is made to reduce the adhesion when applying, but keep strong adhesion after application to prevent from peeling off, which is one of the many unique characteristics of Syncshiled.

- Use dedicated mounting liquid upon application of Syncshield.

- Please use with SENSHA Brand products upon maintenance, daily car care and car wash.

* We cannot assure quality when used with other Brand products and will not be part of the warranty.

In order to further expand the SENSHA Brand, we are looking for partners globally.

If you are interested in finding out more about this opportunity, please fill the form and send us your information.

Our representative will contact you shortly.